This article is no longer actively maintained. While it remains accessible for reference, exercise caution as the information within may be outdated. Use it judiciously and consider verifying its content in light of the latest developments.

-----

Setting Minimum Efficiency Performance Standards (MEPS) at the point of Least Lifecycle Cost (LCC) is generally considered a best practice for sustainable product policy.

However, the team at Coolproducts challenges this mantra. In their report ‘Fine-tuning the Ecodesign engine’ (http://coolproducts.eu/policy/fine-tuning-report) they find that equipment cost is often overestimated while savings potentials are underestimated, leading to sub-optimal results. Therefore, they advocate setting MEPS at higher levels than the LCC point in order to compensate for this bias.

Setting a higher MEPS also makes sense from another perspective, to take into account the environmental cost of energy use. Materials in equipment can be reused or recycled, but energy is consumed, and its externalities are only very partially internalised.

Would you agree to set MEPS significantly above the minimum LCC point? Would there be sufficient public and industry support for such a policy? And if not at the minimum LCC point, at what point should MEPS be defined? Does the break-even point defined by Coolproducts make sense?

These are just some of the questions opened out to Leonardo ENERGY members for discussion, and below is a summary of their replies.

Defining the LLCC and the break-even point

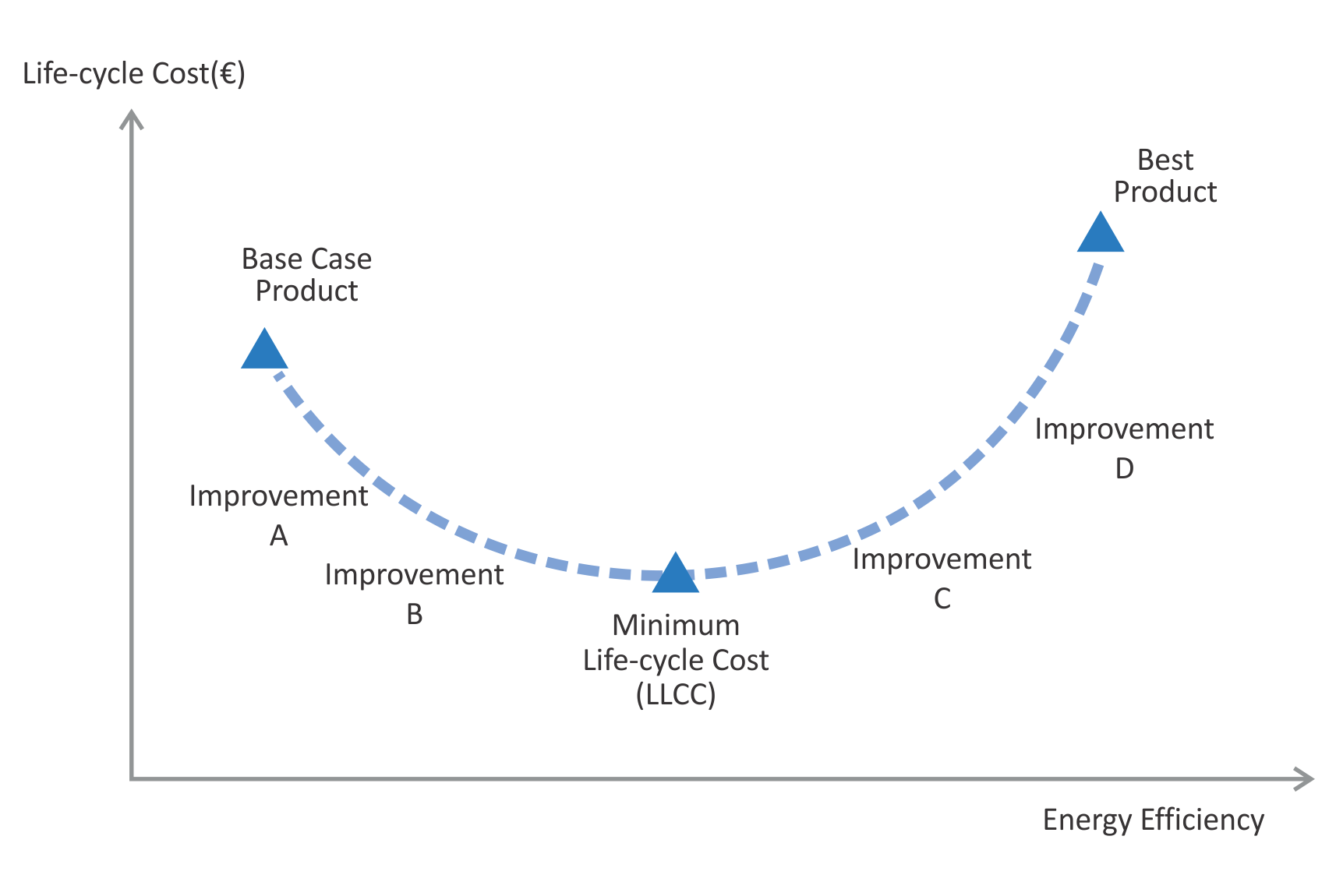

Firstly, a short explanation of LCC and LLCC. If all available (and quantifiable) technical improvements are ranked by their LCC impact and implemented one after the other on a typical product, the LCC of the product will first decrease, reach a minimum and then go back up when the least cost-effective improvements are added. The minimum is the point where it is theoretically impossible to add another improvement that would further lower the lifecycle cost of the product. It is called the minimum or least lifecycle cost (LLCC) (see figure below).

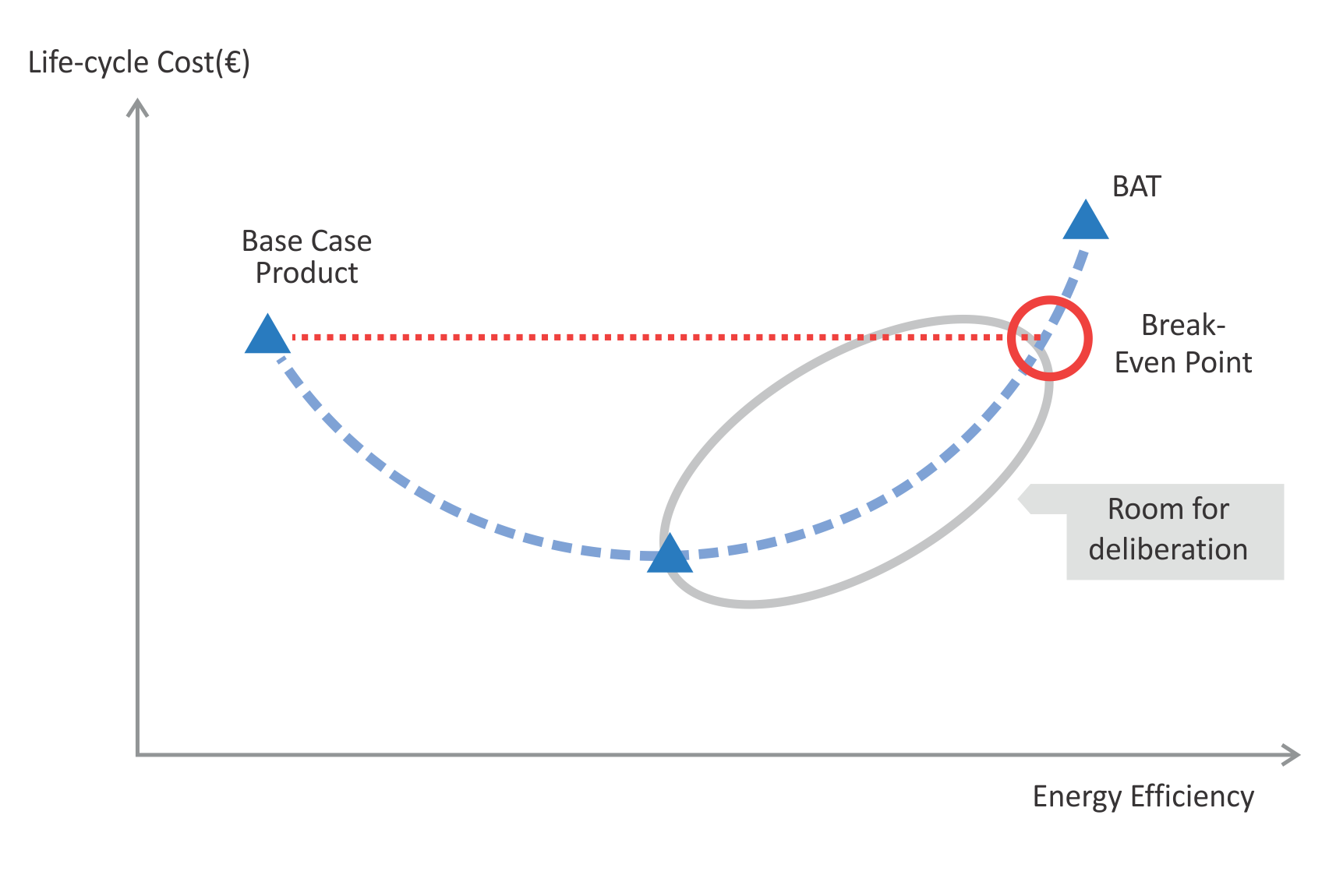

An alternative approach suggested by Coolproducts is to guarantee that the LLC for consumers is maintained at a level not higher than that of the base case, but not necessarily minimised. This means that Ecodesign requirements could be set at a level of energy performance in between the LLCC point and the point where the LCC becomes equal to that of the base case. The latter point - called the break-even point - is the maximum efficiency level that still guarantees that the overall LLC of the product does not exceed that of the base case (see figure below).

Dealing with uncertainties around potential savings

Surprise was expressed at Coolproducts’ assessment that pricing is overestimated and savings are underestimated, as this is rather contrary to what is often seen in studies, which indicate that optimistic (low) incremental cost and high savings are not taking into account some of the market distortion effects such as product teething issues, rebound effect etc.

There was agreement in regard to the environmental impact, as the signs are clearly evident that the planet cannot sustain the present growth, and that if forthcoming action is insufficient, direct costs are unavoidable. The drawback is that this would constitute another form of environmental tax for the end user, in the sense that they cannot recover the investment cost from the savings. This is an important and significant debate in several jurisdictions, where the tax payer may no longer be able to absorb further fiscal or environmental charges.

It was pointed out that the environment is becoming a vital priority and there are obviously difficult choices to make. One of these is that citizens and enterprises will have to pay more for environmental issues and less for other discretional expenses. Enterprises will pass the extra cost to their customers so ultimately a lot of those charges will eventually fall to the individual taxpayers.

This is a clear reminder of the uncertainties regarding cost estimates. However, considering the weak correlation observed between price and efficiency levels, it’s food for thought as to whether final users could not give up some advanced features in an appliance, and use the savings to opt for a high level of efficiency. In such a manner, energy efficiency could become almost cost-neutral.

Distinguishing between developed and developing countries

In South Africa, electrical safety has become a very important subject, driven by the appearance on the market of sub-standard fittings from abroad. It would appear that price is the most important factor when electrical components are purchased. In this respect initiatives such as SAFEhouse (an association of organisations in the South African electrical industry to combat the prevalence of unsafe products and services in South Africa) and the South African Bureau of Standards (SABS) Design Institute Awards are important to educate not only the industry, but the public.

This demonstrates that we probably need to distinguish between developed and developing countries. In developing countries, MEPS serve a function to take the worst products from the market. Also, there is an electrical safety dimension. Developed countries on the other hand should take the lead in setting the high standards they can afford.

Maintaining the need for consumer choice

The impact on consumer choice (exclusion of some product types from the market) and the maturity of the supply market to deliver efficient products must also be considered.

For some appliances, there is little relationship between energy efficiency and product cost. In such cases, applying the LCC rule should result in the highest efficiencies. Many items of office equipment fall into this category with practically all major suppliers displaying the Energy Star logo.

As to moving away from setting Ecodesign requirements based on minimum LCC towards setting the requirement at a range between LCC and the break-even point instead, it was remarked that the justification to set the MEPS at the break-even point is weaker than the one at minimum LCC.

For many countries, MEPS levels depend on trends in major markets. Hence, implementation can be faster, the LCC analysis is more current and more frequent reviews can be carried out.

Realizing that LCC is not the only factor

It’s certainly an interesting point that LCC is not the only consideration, but market characterisation is also required. Benchmarking with other jurisdictions is also done frequently as an additional check to ensure that a proposed MEPS could be reasonable in a market.

An interesting comment from one LE member who was recently in Africa is that the trend in several countries with limited electricity supply is to push to adopt higher MEPS and force a more rapid market transformation, rather than going with a slow approach that locks-in a large quantity of inefficient equipment in the market. In those countries, the extension of product life beyond what is done normally is another concern, as some equipment seems to have an almost infinite life.

A few concluding thoughts

- It’s not always easy to obtain representative data for LCC. Manufacturers typically provide information on products, but not on their use. Users may have good information on this, but may not know the parameters for alternatives that could be more or less efficient. Consultants are neutral but may not have ready access to the information needed to compile an LCC.

- When plotting LCC as a function of efficiency, it is regularly observed – e.g. for industrial equipment – that the curve is quite flat. This leads to a wide range of almost equivalent optima. In other words, we have a low efficiency optimum with low CAPEX and high OPEX, naturally preferred by users; and we have a high efficiency optimum, with very similar LCC, with high CAPEX and low OPEX, which is preferrable from a societal perspective.

- Changing the slope of the flat LCC curve could be achieved by including external factors (e.g. pricing carbon) or by stringent End of Life regulation. Both appear difficult, so setting a high MEPS level may be easier.

- Especially for markets where efficiency is very low, it might be good to go for higher MEPS, since there will still be a payoff for the investment, while avoiding lock-in of medium efficiency equipment (a point which was raised in the discussion).

- High MEPS would be most beneficial in developing countries, where generation capacity is scarce. However, there are many demands on scarce capital in developing countries.

- Availability of product is an issue (as pointed out in the discussion). Could this be managed by foreseeing adequate transition periods?

- MEPS cannot be set in a vacuum. An undesirable scenario for manufacturers would be to have too many different MEPS in various countries. Organisations such as IEC and CLASP have a role to play.

Thanks to comments received from Pierre Baillargeon, Evert Swanepoel, Val Boyanov and Ram Bhaskar.

-----

Document history:

- May 2015: initial post following a discussion on LinkedIn

- Nov 2022: minor edit; retrieval of the 2013 CoolProducts report

-----

Comments

0 comments

Article is closed for comments.