Power cables can typically be expected to operate for 40-50 years or more. It would therefore make sense for investment decisions to be based on the operational life of the cable. However, in many cases, this is not so. Decisions are often taken based on the purchase cost and other short-term costs and fail to take into account potential savings during the long-term use of the cable.

Life-Cycle Cost Analysis

The total cost of ownership of cables (hereafter called life-cycle cost) not only takes into account the initial cable cost, but the costs to operate and maintain the cable over its lifetime, and thus includes both CAPEX and OPEX. This makes it possible to calculate the real economic choice between cables of different conductor materials, such as copper and aluminium.

A Life-Cycle Cost Analysis (LCCA) can be used to find the most cost-effective solution for a project with multiple options. Typical areas of expenditure which are included in an LCCA include purchase cost, operation and maintenance, residual value, electric losses, and costs of disposal. All costs are discounted and totaled to a present day value; known as the Net Present Value (NPV). An LCCA therefore gives an excellent insight into the total costs associated with underground cables.

Comparing copper and aluminium

Once an LCCA is conducted, it clearly shows that the significant purchase price difference between raw copper and aluminium is only a small part of the total costs over the lifetime of an underground cable.

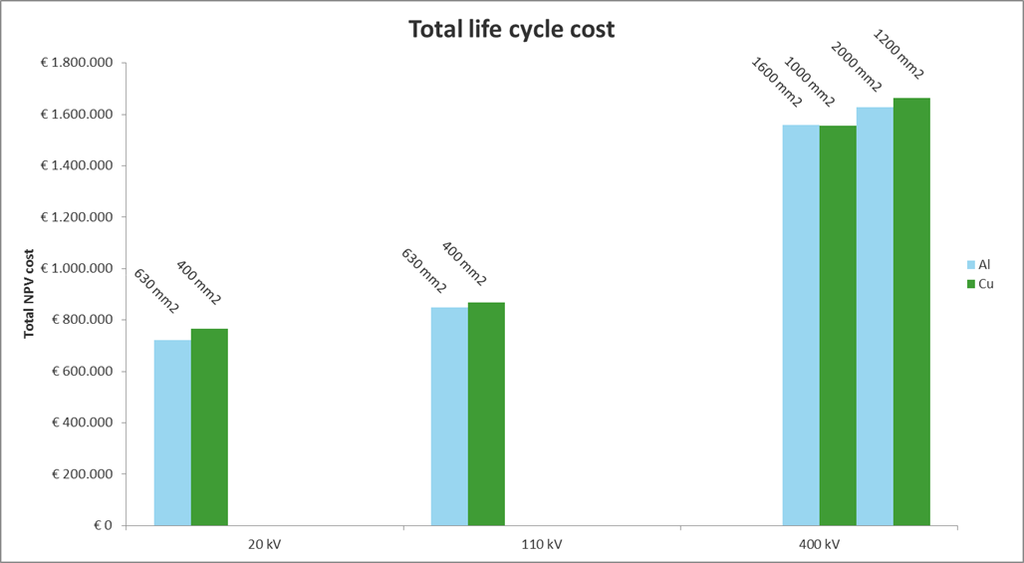

In the figure below the total life-cycle costs (in EURO) are given per voltage class 20, 110 and 400 kV and per cross-section (the cross-sections per voltage give a comparable current rating for copper and aluminium). It can be seen that there is minimal difference (on average 3%) in total life-cycle costs between copper and aluminium conductor cables over their operational lifetime.

Implications

As a conductor, copper costs a multiple of aluminium. However, looking at lifetime costs, and within the uncertainties over the very long cable lifetime, the economic advantage of using the initially less expensive aluminium rather than the more expensive copper solution rapidly evaporates.

Reference

http://www.jicable.org/2015/content/Programme/pdfCreator/242_E1.2_JICABLE15_0039.pdf

-----

Last update: June 10, 2022

Comments

0 comments

Please sign in to leave a comment.